Cleveland, OH – Cleveland Black Oxide, the largest commercial black oxide conversion coater in the U.S., has installed larger tanks to accomodate steel parts up to 17 ft. in length and weighing up to 8,000-lbs. These are believed to be the largest tanks in the industry.

Cleveland, OH – Cleveland Black Oxide, the largest commercial black oxide conversion coater in the U.S., has installed larger tanks to accomodate steel parts up to 17 ft. in length and weighing up to 8,000-lbs. These are believed to be the largest tanks in the industry.

Bob McElwee, Cleveland Black Oxide’s President says: “The larger tanks not only allow us to handle larger parts, but smaller parts as well in larger quantities.”

In addition to the larger tanks for steel parts, the company has 12 ft. tanks for stainless steel and 4 ft. tanks for copper, brass, bronze, and die cast zinc.

“Our large tanks allow us to do a lot of off the wall parts, says McElwee. We’ve done large architectural panels for hotel lobbies and even the stainless steel netting covering the aviary at the Miami Zoo.”

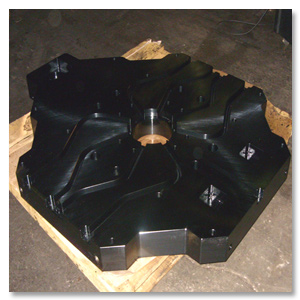

The bulk of Cleveland Black Oxide’s business is still automotive, industrial, hardware, medical and consumer products, but customers are continually thinking up new applications. Recently the company received orders to black oxide 20-ft x 30-ft. x 0.010” copper sheets used to adhere magnets used in MRI machines.

“Once engineers and designers learn what a great finish black oxide is, it really sells itself, adds McElwee. Most people don’t realize that black oxide really isn’t a coating at all. Black oxide is the resultant change in appearance and physical properties when metallic iron surfaces are immmersed in a hot salt solution. There is no dimensional change, no weight is added and it’s environmentally friendly.